The popularity of lean management has exploded in recent years. More and more companies are adopting lean techniques in an effort to improve efficiency, profitability, and customer satisfaction. By making process improvements that eliminate waste, they’ve been able to save time and money in their businesses.

In addition to the financial benefits, lean management also enables businesses to make full use of their most valuable assets: People. According to research by the McKinsey Global Institute, it’s estimated that at least 30% of the activities in 60% of all occupations could be more streamlined. This offers the potential for freeing up people’s time to make even more valuable contributions.

In this article, we look at the key principles of lean management and how it can benefit your business.

The Meaning of Lean Management

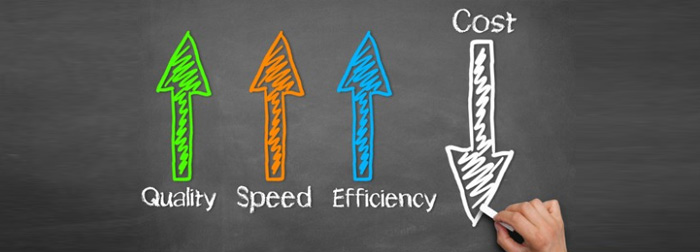

Let’s start by taking a look at exactly what ‘lean management’ means. The Lean Enterprise Institute describes it as ‘maximizing customer value while minimizing waste’. It’s about creating more value for your end-customers but using fewer resources along the way. Delivering greater value results in better satisfaction and more sales. Doing so with fewer resources means your business operates more efficiently and profitably.

Many proponents of lean manufacturing take this a step further by including continuous process improvements. This allows them to make small but consistent progress towards their goals without having to overhaul an entire system or approach. An introduction to lean management can, therefore, be summed up with three key concepts:

- Delivering more customer value

- Minimizing waste

- Continuously improving

Who Benefits?

The beauty of lean thinking is that is can be applied to any industry or business model. Whether you work in software development, manufacturing systems, or industrial engineering, you can apply the principles of lean to your operations. It benefits your customers, your team members, and your shareholders (if you have them). Here are just of few advantages of the lean methodology:

- More efficiency – puts productivity at the heart of your business activities and eliminates waste.

- Improved focus – a learn enterprise allows staff to focus on doing the things that drive the greatest value.

- Streamlines resource usage – lean leadership enables your business to operate based on real-life demand instead of over-estimates so that you use the correct resources which delivers cost reductions.

- Increases adaptability – lean management allows you to deliver projects based on demand rather than pre-emptive projections.

The 5 Principles

There are five lean management principles that underpin this approach to business. These are:

- Identify value

- Map value streams

- Develop continuous workflows

- Create a pull system

- Continuous improvement

When these lean principles are combined into a company’s processes and culture, they create lean production, manufacturing, and operating systems. In this section, we dive into each of these in a bit more detail.

#1 – Identify lean value

Creating value is at the core of every business. It’s the reason that customers are willing to pay for our products and services. If you don’t solve a customer problem or create enough value, then they won’t be willing to part with their cash.

The first step is, therefore, to identify the value to the customer that you want to create. Anything that doesn’t contribute to this is considered superfluous. This is one of the key goals of lean so it’s important to be clear on your objective from the outset.

#2 – Map value streams

Value stream mapping is where you figure out the workflow. What is the exact production system and who is involved? By clarifying everything in your business process, you can identify any parts that don’t contribute value to the customer.

Once you’ve mapped your value stream, it’ll be easy to see which parts of the process deliver value and opportunities for reducing waste. It also gives you a big picture overview, allowing you to identify the teams taking ownership of different stages and the potential for lean transformation.

#3 – Develop continuous workflows

Once you have your value stream mapped, you’ll need to turn it into continuous workflows. A typical production process involved several different teams, materials, and steps that occur in tight sequence, so it’s important that these are all coordinated. If the flow stops moving for any reason, then it’s inevitable that wastage will occur (particularly wasted time). Visualizing a workflow and dividing it into smaller sub-sections is an effective way to predict potential barriers and address them up-front.

#4 – Create a lean management pull system

A pull system involves creating based on actual demand instead of forecasts. In order for flow to operate smoothly, things shouldn’t be manufactured ahead of time because if unused, this creates waste. Instead, creating a pull system allows you to make products or develop services in response to customer orders. To be successful, you’ll need a short cycle time so that you can deliver quickly. But because you’ve adopted lean thinking, mapped value streams and created continuous workflows, this will now be easy.

#5 – Continuous improvement Software

The first four steps will help you create a lean management system but it’s this final step that will ensure you thrive. At this stage, you can revisit any aspects of the process that have opportunities for improvement. By continually striving to get better, you’ll increase efficiency and productivity on a consistent basis. You’ll also be able to improve products and enhance services, leading to greater customer satisfaction.

When these lean management principles are combined, they provide a powerful framework for sustained growth. Manufacturing organizations that successfully implement them create a distinct competitive advantage that others will be unable to rival. Identifying value ensures that your business focuses on those elements that customers most appreciate. Mapping value streams allows you to see exactly where it is created as well as which parts of the process aren’t contributing. Developing continuous workflows ensures that everything works in harmony and as efficiently as possible. With a pull system in place, resources will be perfectly aligned with demand and waste will be dramatically reduced. Continually improving processes will ensure you stay ahead of the curve and are consistently at the forefront of your sector. Organizations that adopt this approach are setting themselves up for long-term success and profitability.

What Are the 8 Wastes of Lean?

You might also have heard another term related to lean production: the eight wastes of lean. These are areas that are the root cause or contributors to inefficiency. They are often associated with the acronym ‘DOWNTIME’ which stands for defects, overproduction, waiting, non-utilized talent, transportation, inventory, motion, and extra processing. Let’s look at each of these types of waste in more detail.

- Defects – creating products, services, or information that isn’t accurate or is missing parts.

- Overproduction – this isn’t just about making more of something than you need. It can also refer to making it too soon or too quickly, resulting in unnecessary storage costs.

- Waiting – losing time while you wait for supply chain materials, people, or information. This could include waiting for equipment to be delivered or approvals to be received from project stakeholders.

- Non-utilized talent – not making full use of your team’s skills, experience, or creativity. This can sometimes take the form of highly skilled employees spending time on relatively unskilled tasks.

- Transportation – moving equipment or materials unnecessarily can lead to additional reviews or steps that aren’t required. This also applies to the movement of information, such as sending emails.

- Inventory – allowing parts or information to build up beyond the amount needed. Stockpiling or hanging on to data longer than needed are both examples of this.

- Motion – this is the movement of people in areas that don’t benefit the customer, such as walking between different equipment or typing keystrokes repetitively.

- Extra processing – additional steps that don’t benefit the end-customer, such as formatting or extra features they don’t value.

These waste areas provide a helpful starting point for manufacturing companies looking to adopt lean management. Think of them as a checklist to review or signposts to where your organization can increase efficiency. When managers look at each of these areas, in turn, they always find opportunities for improvement and overlooked sources of waste. These are elements that have been identified as problematic for organizations time and again so it’s worth learning from others’ mistakes. For businesses that are serious about adopting lean manufacturing principles, reviewing the eight wastes in the context of their own operational processes is essential.

Software To Drive The Process

Using lean management software can streamline the entire process and help you visualize it effortlessly. Continuous improvement becomes a hundred times easier with lean tools like our innovative digital platform. Using the Rever dashboard, you can monitor the performances of teams, understand their impact, and easily identify the people making the biggest difference at your company.

Digital platforms like ours make the entire lean management process easier and more efficient. They provide a single repository for ideas and best practices in your organization so that everyone can benefit from hive knowledge. This is especially helpful for avoiding siloed thinking and opening up communication between teams and departments. Because the information is stored in the cloud, it can be accessed by anyone with a tablet or mobile device. This makes it ideal for frontline factory workers and staff who don’t have easy access to laptops or desktop computers. Ideas and updates can be input on the go while progress reports are available instantly at their fingertips. Our software reduces the need for back and forth emails, spreadsheet plans, and bottlenecks in the flow of information. So, administration is reduced, communication is improved, and time is freed up for the actual implementation of lean processes.

The Rever Cycle is our version of the PDCA methodology that guides teams on the exact steps to follow to execute their own ideas and achieve continuous improvement. It allows them to capture the entire process, from identifying a problem to experimenting and implementing a solution. They can use it to capture the before and after with pictures, notes and drawings, making their ideas a reality in no time. The time of your team is too valuable to be wasted in handmade drawings and complex explanations. So, we created Rever to help you with implementing lean management in your business.

How We Can Help

At Rever, we believe that anybody can be a knowledge worker, contribute to the organization’s success and thrive in their work through their contribution. What makes us human is the capacity to grow our intellect and will, and to use them for good. We observe, especially at work, that most people are asked to stop thinking and do as they are told. We want to change that. We enable people to achieve their full creative potential.